In one of the world’s most competitive industries, we support our clients with our industry experience and technical expertise. We realize operational excellence through digital processes and delivery optimization, by improving margins and increasing volumes and by introducing optimal international value chains. We optimize the service portfolio, increase R&D productivity and ensure efficient order fulfillment, be it for engineering projects, the production of standard and special-purpose machinery or in component manufacturing.

Realignment of the operative business

Business analysis and setting up measures to increase profitability in the core business, among other things, by improving operational order processing and reducing costs through plant relocations.

Results: Results are subject to a non-disclosure agreement

Role: CEO

Tracking and optimization of worldwide order processing

Set-up and coordination of ProMTO to ERP systems for software-based optimization of order portfolio.

Result: Development cooperation for further development of ProMTO, tool development completed

Role: Consultant

Development of a new group strategy

Definition of a group strategy process focusing on ESG, core competencies and pricing. Development of an Asia-Pacific regional strategy and assessment of portfolio options.

Results: Existing strategy approaches unified, aligned to group objectives and then handed over to business units and regions

Role: Head of Group Strategy (Interim)

Expansion of production capacities through the construction of a new assembly plant for packaging machines (fibre and plastic) in Eastern Europe

Realignment of operations strategy to increase productivity and capacity. Site search, selection, securing and development of a new assembly plant in Eastern Europe. Sparring partner for management and operations managers.

Results: New operations strategy, successful search process in three Eastern European target regions and analysis of 25 sites. Selection, negotiation, contract conclusion and ramp-up of the final site. Thus securing production capacity for planned sales growth

Role: Project Manager Expansion Operations (Group)

Reorganisation and turnaround of the solutions business unit of a global intralogistics group

Establishment of a global Business Unit within a matrix organization and steering of the business unit through the Covid-19 crisis. Alignment of the business unit and regions to the defined turnaround goals. Improvement of the order intake quality (volume, margin) and result improvement by optimizing the multi-project execution.

Results: Turnaround due to significant increase of order intake and margin, reduction of loss-making projects, optimization of the multi-project execution, successful launch of the new business unit.

Role: Head of Global Logistics Solutions Business Unit

Managing the global Business Units and leading a performance improvement program

Managing of eight business units and three engineering groups. End-to-end performance improvement of the solutions business through business model adjustment, optimization of the multi-project execution, modularization of the solutions portfolio and restructuring as part of an international transformation program.

Results: Turnaround achieved via significant ROS-uplift in the operative business.

Role: Head of Business Units, Head of Turnaround Program

Turnaround of an Italian packaging machine manufacturer through efficiency improvement

The mandate involved leading the entire team and comprehensively aligning them to the turnaround goal, introducing analytics-based project management in parallel and redesigning key products. Upon completion of the year-long mandate, we trained up a new permanent manager prior to handing over business responsibility to him.

Results: Double-digit ROS uplift achieved in the business unit, critical personnel retained, successful handover to permanent manager, further ROS improvement achieved after end of mandate partly through providing the client with analytics support for two years.

Role: CRO

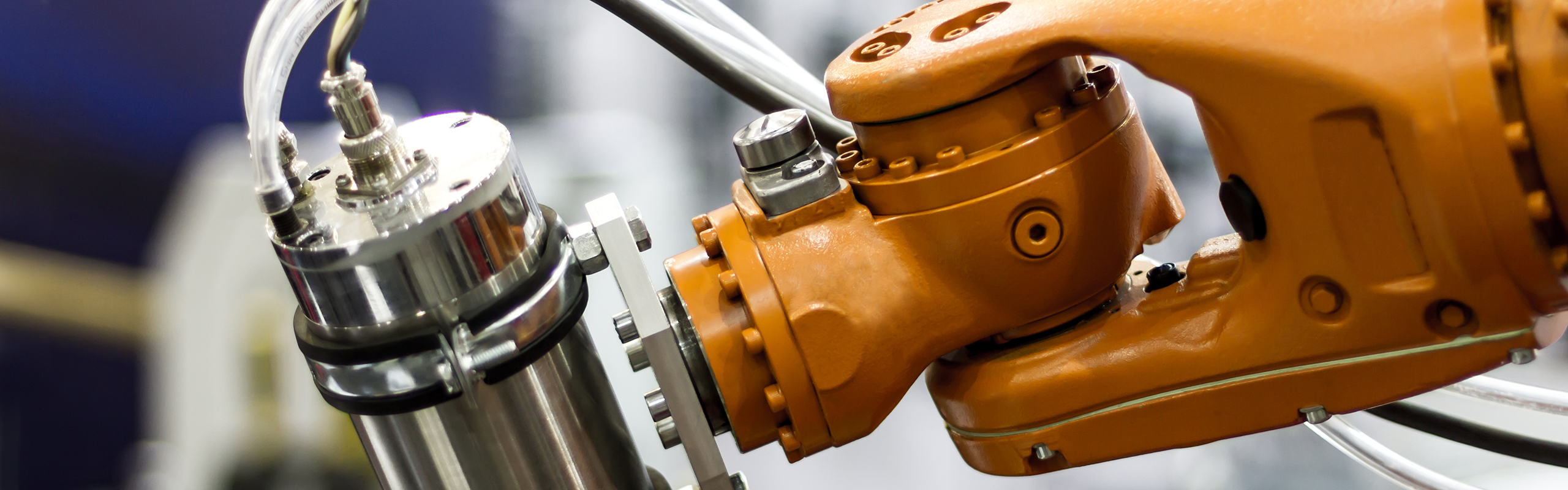

Restructuring and carve-out of a group company manufacturing robotics and visual inspection systems, automation technology and machine tools

Management improved, products standardized, marketing intensified and rigorous cost management introduced. Subsequently carved out parts of the company.

Results: Restructured and repositioned the company, increased ROS, achieved successful carve-out in consensus with stakeholders.

Role: CEO

Turnaround of a machinery and industrial services group, basis for a planned sale

In the run-up to the sale of the energy and oil & gas division, we extensively restructured the company’s international branches, established a new management team and increased the margins in the individual business units as a prerequisite for initiating the sale process, which has since been completed.

Results: Return to profitability after one year through restructuring across business locations with workforce reductions in several countries. The division was later sold to a private equity company and is now operating successfully as an independent company.

Role: CEO

Stabilization, restructuring and turnaround of a European engineering and industrial services company

Highly loss-making Belgian subsidiary restructured in accordance with local law with reconciliation of interests and social plan, project management improved, new management team installed.

Results: Successful restructuring within seven months; double-digit ROS uplift achieved in parallel. Retained key performers; withdrew from the high-risk major projects business; since then the company has been operating profitably once more under new management in its original core business.

Role: Advisory Board Chairman, CEO of parent company

Restructuring of an engineering service unit and sale via asset deal

Service unit for the maintenance of large-scale chemical plants sold to a strategically focused competitor via asset deal and transfer of operations pursuant to Section 613a of the German Civil Code (BGB).

Results: Operations continued uninterrupted, successful transfer of operations achieved with the approval of the entire workforce and the customers. Company has since been successfully repositioned by the buyer and the business expanded.

Role: General Manager

Product cost reduction for a printing machine manufacturer’s new digital printing press

Costs for an innovative digital printing press reduced in the development phase through comprehensive design-to-cost measures.

Results: Cost reduction target achieved for the product line.

Role: Consultant

Cost optimization for existing and new products in offset and digital printing for a world-leading manufacturer of printing machines

Product design optimized for production and rigorous supplier management introduced. Manufacturing costs significantly reduced.

Results: Contributed to cost reductions and ensured start-of-production for various lines.

Role: Consultant